Heat, moisture (yes, even here!), and heavy use can take a toll on concrete garage floors. A garage floor coating can withstand this abuse only if the surface beneath it is prepared correctly. Skipping or rushing this step almost guarantees peeling or failure later.

The most reliable way to judge surface readiness is through the Concrete Surface Profile (CSP). What does that mean, exactly? We’re so glad you asked!

Understanding CSP Ratings

The CSP scale measures the roughness of concrete. Think of it as a way to match the coating to the texture beneath it.

- CSP 1: Very smooth, not suitable for bonding

- CSP 10: Very rough, unnecessary for residential garages

- Target CSP for garage floor coating: 3–4

This middle range creates a texture that allows coatings to grip securely without overworking the surface.

Why Some Methods Fall Short

Not all surface prep techniques achieve the right CSP. Some are too light, others too aggressive.

- Acid etching: Too smooth, doesn’t provide long-term bonding strength

- Low-pressure water jetting: Also too smooth!

- Sandblasting / rotomilling: Overly rough for most garages, not needed in Phoenix homes

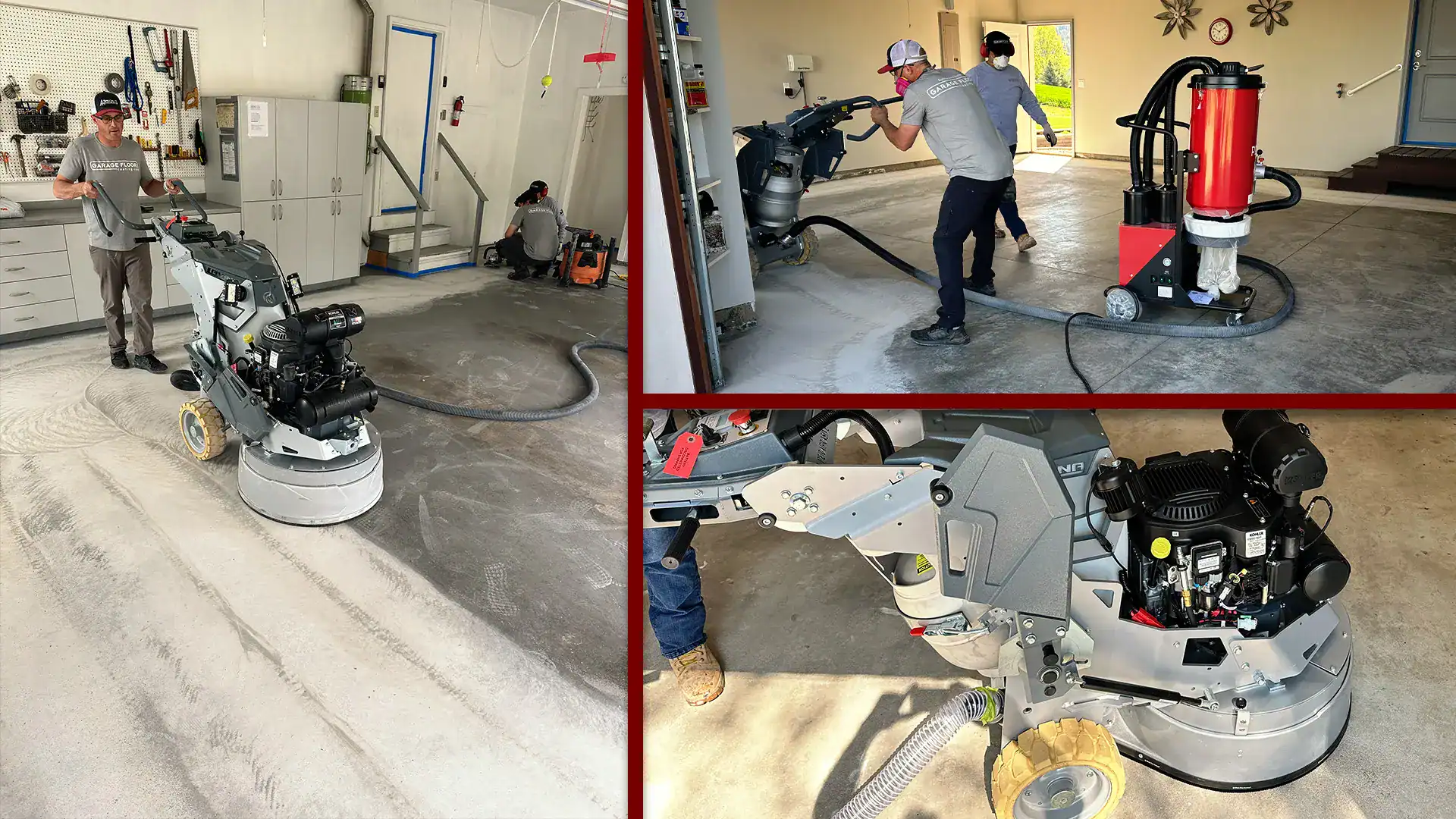

- Grinding: Reliable way to consistently achieve CSP 3–4

Propane vs. Electric Grinders

In Phoenix, where garages are often large and used heavily, the type of grinder matters.

- Propane grinders

- Strong and efficient

- Covers large spaces without cords

- Better for speed and consistency

- Near-zero emissions (great for tight, indoor spaces)

- Electric grinders

- Less powerful and slower

- More labor-intensive over time (if you want a quality floor out of it)

Contractors who invest in propane grinders (they’re expensive!) can prepare floors faster and more effectively, which translates into coatings that hold up better in high-traffic and high-temperature environments.

Why It Matters in Phoenix

Arizona’s extreme heat and dust put extra stress on floors. A poorly prepared surface will make any garage floor coating vulnerable to lifting, especially near vehicle tires where the most heat and pressure occur. By achieving a CSP in the 3–4 range with proper grinding, concrete coatings bond securely and stand up to local conditions.

Don’t Skip Prep, Hire the Pros

Long story short:

- CSP 3–4 is the “sweet spot” for adhesion

- Grinding is the best way to achieve this surface profile

- Propane grinders outperform electric grinders for speed and power

- Without proper prep, even the best garage floor coating won’t last

You want professionals coating your garage. DIY projects or one-day coatings all sound tempting, but that’s how you wind up with expensive floors that just peel and crack a year or even months after installation.

If you want it done right the first time, invest in a quality coating that won’t wind up costing more in the long run. That’s what we’re passionate about, and if you’re interested in chatting about it, we’d love to hear from you. Shoot us a message or give us a call.