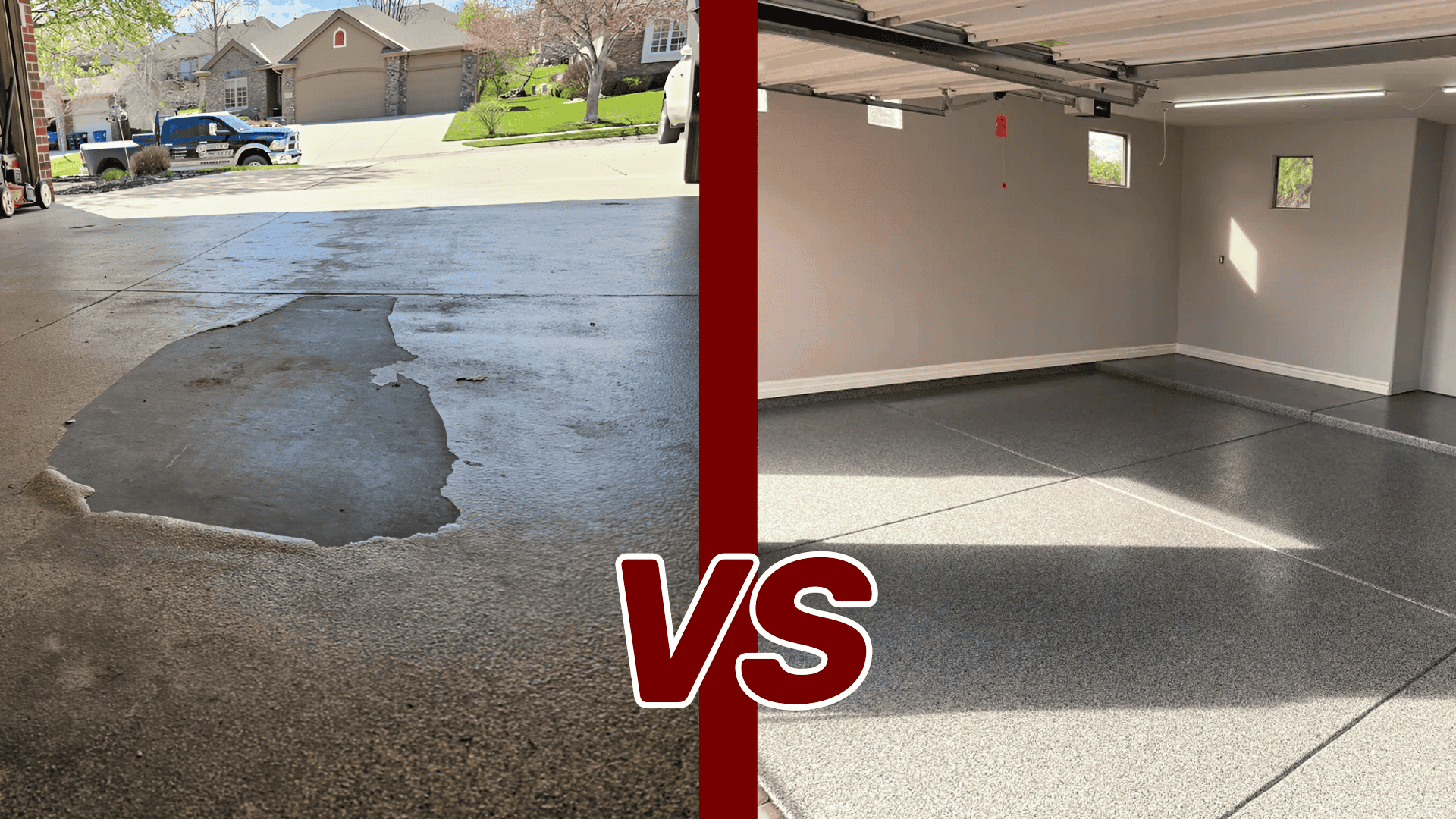

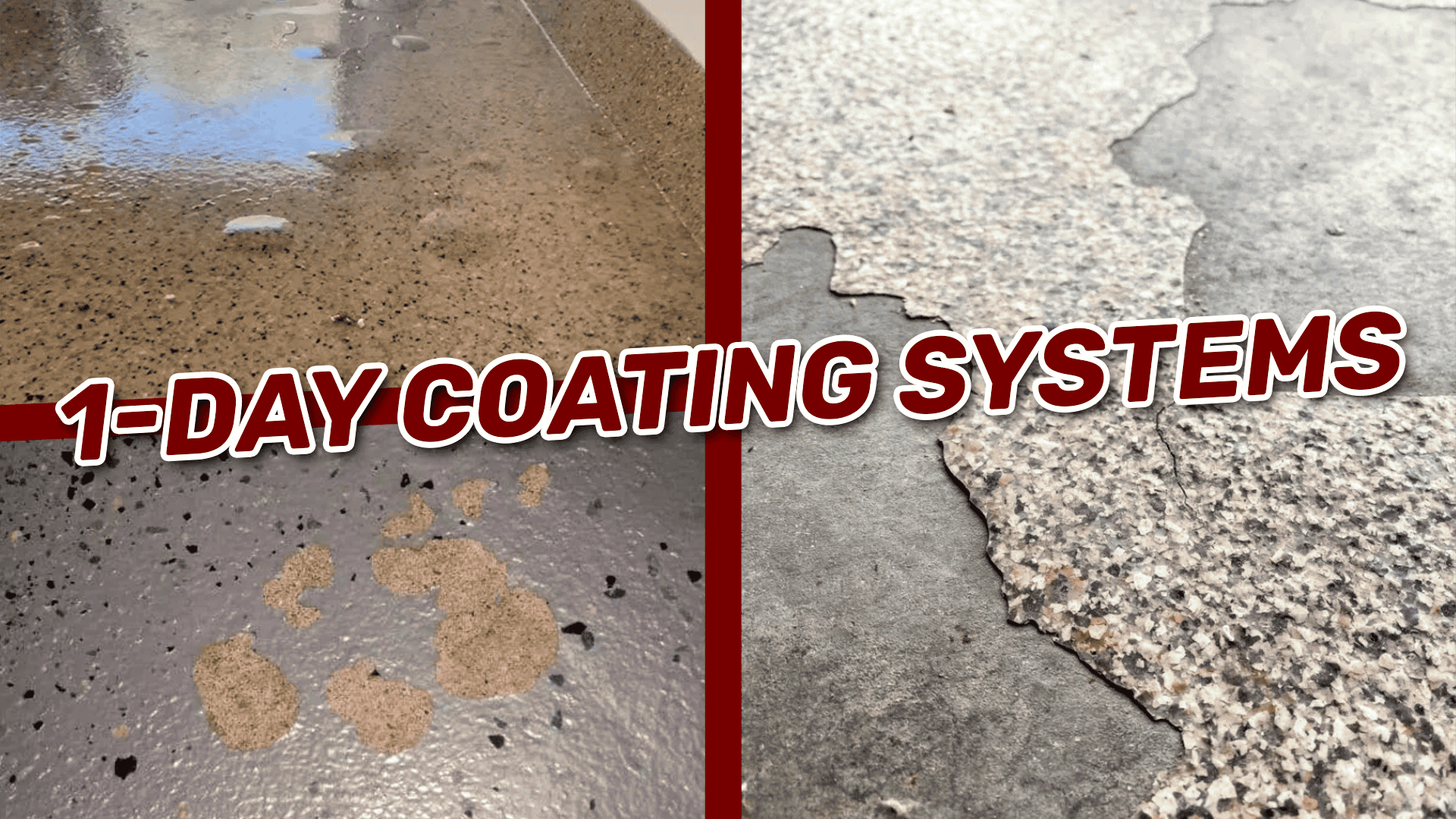

Across Phoenix, “1-day” garage floor coating services are everywhere. They promise a brand-new floor by dinnertime, but what most homeowners don’t realize is that many of these companies skip an essential step called moisture mitigation. It’s what protects your floor from vapor pressure that builds beneath the surface. Without it, even the best-looking garage floor coating can start peeling, bubbling, or delaminating far sooner than you’d expect.

Why Skipping the Primer Is a Costly Shortcut

The biggest mistake fast-installers make is applying a polyaspartic or polyurea coating directly to bare concrete without sealing it first with a moisture-mitigating epoxy primer. That primer does two critical things: It locks out ground moisture and creates a strong foundation for adhesion. When it’s skipped, vapor gets trapped under the surface and pushes upward until the coating breaks free.

Once that happens, the floor you just paid for can start failing in less than a year.

Fast-Curing Products Make It Worse

Polyaspartics and polyureas are designed to cure fast. That’s great for saving time, but terrible for bonding strength. Because they set so quickly, they don’t have time to soak into concrete. Even manufacturers like ArmorPoxy and VersaFlex warn that these products should be used as topcoats, not primers. Yet, many “1-day” companies use them as all-in-one solutions to meet a same-day deadline.

What Experts and Standards Recommend

Industry leaders like Sherwin-Williams (General Polymers), Corotech by Benjamin Moore, Sika, BASF, Euclid Chemical, Stonhard, and Eco-CorFlex all agree: proper garage floor coating systems start with moisture testing and a 100% solids epoxy moisture vapor barrier primer. Organizations such as ASTM International, the American Concrete Institute (ACI), and the International Concrete Repair Institute (ICRI) have published similar standards—ASTM F3010 specifically sets the bar for moisture vapor control beneath resinous coatings.

Skipping these steps can void your warranty and almost guarantees premature failure.

The GarageFloorCoating.com (Phoenix) Difference

At GarageFloorCoating.com (Phoenix), we take the extra day to do it right. Every slab is tested for moisture, and when vapor is present, we apply a true epoxy vapor barrier like Eco-CorFlex MME. This system can handle up to 100% relative humidity and more than 20 lbs MVER, protecting against the desert’s hidden moisture and our intense monsoon seasons.

Our coatings are installed to standard, and our warranties actually cover moisture-related issues because we prevent them from the start. For a garage floor coating that lasts decades instead of years, trust the Phoenix team that doesn’t skip steps.