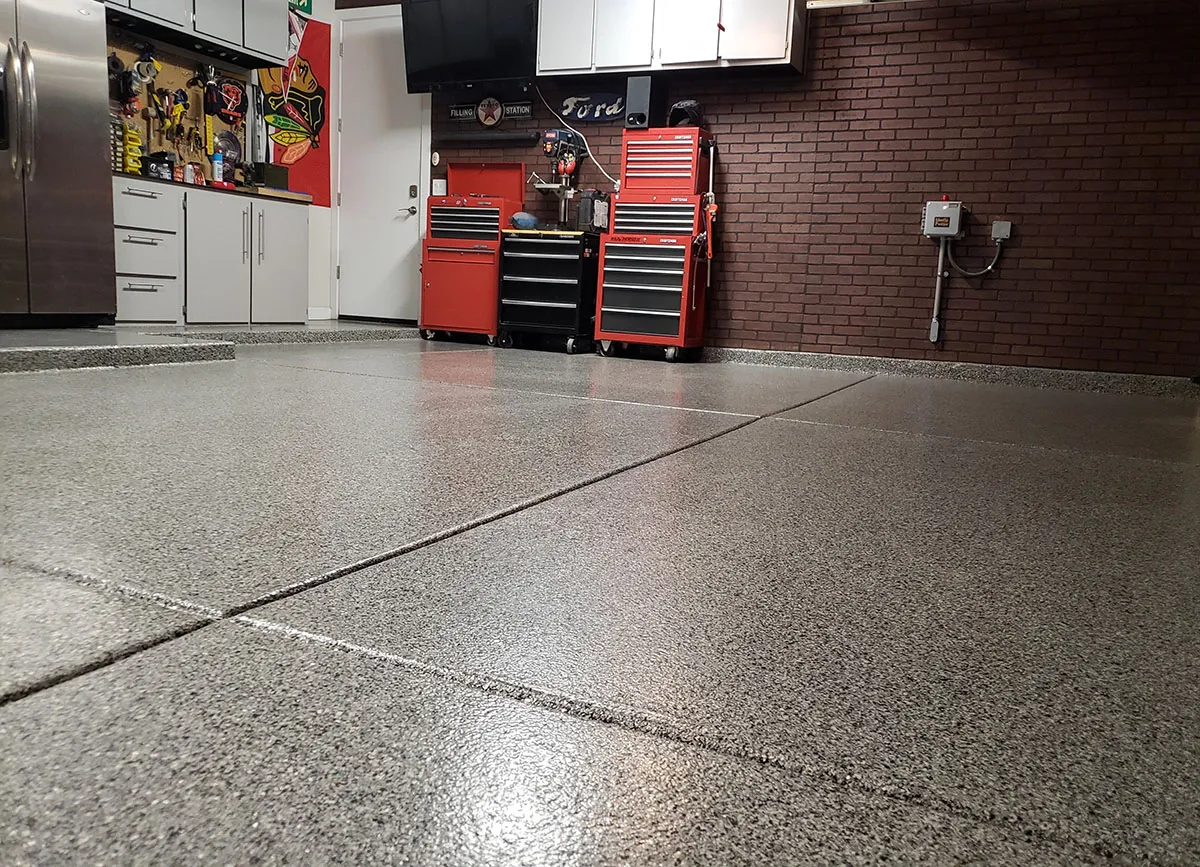

Transforming your garage into a functional, safe, and durable workshop starts from the ground up. With professional, hybrid epoxy and polyaspartic garage flooring from GarageFloorCoating.com (Phoenix), you get more than a sleek look—you get performance you can rely on every day.

Garage Flooring That Withstands the Daily Grind

Whether you’re building furniture, tuning up your motorcycle, or just organizing tools, a workshop demands flooring that doesn’t flinch under pressure. GFC’s epoxy and polyaspartic garage flooring is engineered to stand up to whatever your work throws at it:

- Impact resistant to dropped hammers, lumber, and heavy tool chests

- Chemical resistant to stains, oils, solvents, and other workshop spills

- Anti-skid texture that gives you safe footing even with dust or moisture present

For homeowners who spend real time in the garage—drilling, cutting, welding—this is a surface that won’t wear out under stress.

Moisture Mitigation and Hot-Tire Transfer Protection

In Phoenix, temperature swings and dry-to-wet transitions can wreak havoc on traditional coatings. But GFC’s hybrid epoxy and polyaspartic garage flooring features full moisture mitigation, meaning it helps prevent water from seeping up through the concrete and damaging your slab.

And if your garage is your go-to space for car repairs or auto detailing, GFC has you covered there too. Our advanced polyaspartic topcoats resist hot-tire transfer, preventing the unsightly black marks that come from hot rubber cooling on inferior coatings. That’s a big deal if your garage doubles as a workspace for your car.

The Power of the GFC 2-Day System

You’ve probably seen the ads for 1-day garage coatings. Quick in, quick out. But here’s what they don’t tell you: those fast installs typically rely on a fast-curing polyurea or polyaspartic as the base coat—they cure so quickly in the presence of moisture that they fail to deeply penetrate and strongly bond with the concrete slab. Over time, that shortcut can mean peeling and a failed coating.

GFC does it differently. Our proprietary 2-day installation system prioritizes quality from the ground up:

- Day 1: We mechanically prepare the concrete and apply a thick, 100%-solids, moisture-mitigating epoxy base coat. It acts as a moisture vapor barrier (MVB). It provides strong adhesion, fills surface imperfections, and mitigates for all future moisture-related issues.

- Day 1 (cont’d): Into the “wet” base coat, we broadcast your selected flake blend in a thick, full-flake spread.

- Day 2: We return on day 2 to apply two separate, 100%-solids polyaspartic topcoats for maximum chemical resistance, UV protection, and a flawless, long-lasting finish.

The extra day delivers a surface that holds up under pressure—and looks amazing for years to come.

The result? Garage flooring that mitigates against future moisture vapor transmission and high hydrostatic pressures, resists chemicals and hot-tire staining, and protects against everyday dumps and scratches.

Ready to upgrade your garage into a high-performance workshop? Contact GarageFloorCoating.com (Phoenix) today and get started on a space built to work as hard as you do.